This was a project I worked on in 2018 for JNJ Vision while contracting at Ethicon. It is a machine for laser eye surgery.

It was an extremely interesting project, as it was the largest product I have ever worked on, and I was able to build really cool full size appearance model/s.

A lead designer was over this project, and I assisted and contributed by creating sketch concepts, CAD concepts, renderings, and making full size appearance model/s, working with the lead designer.

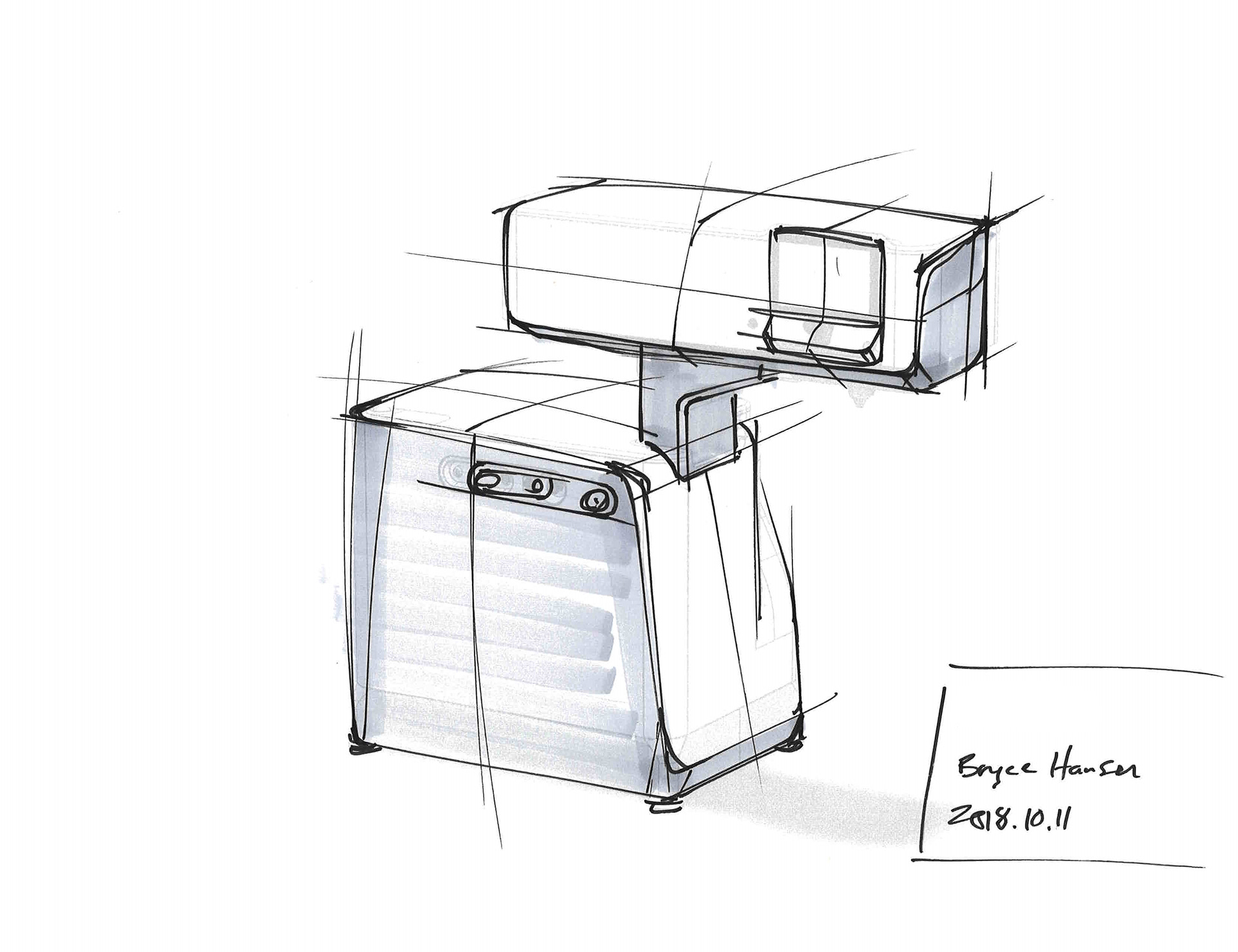

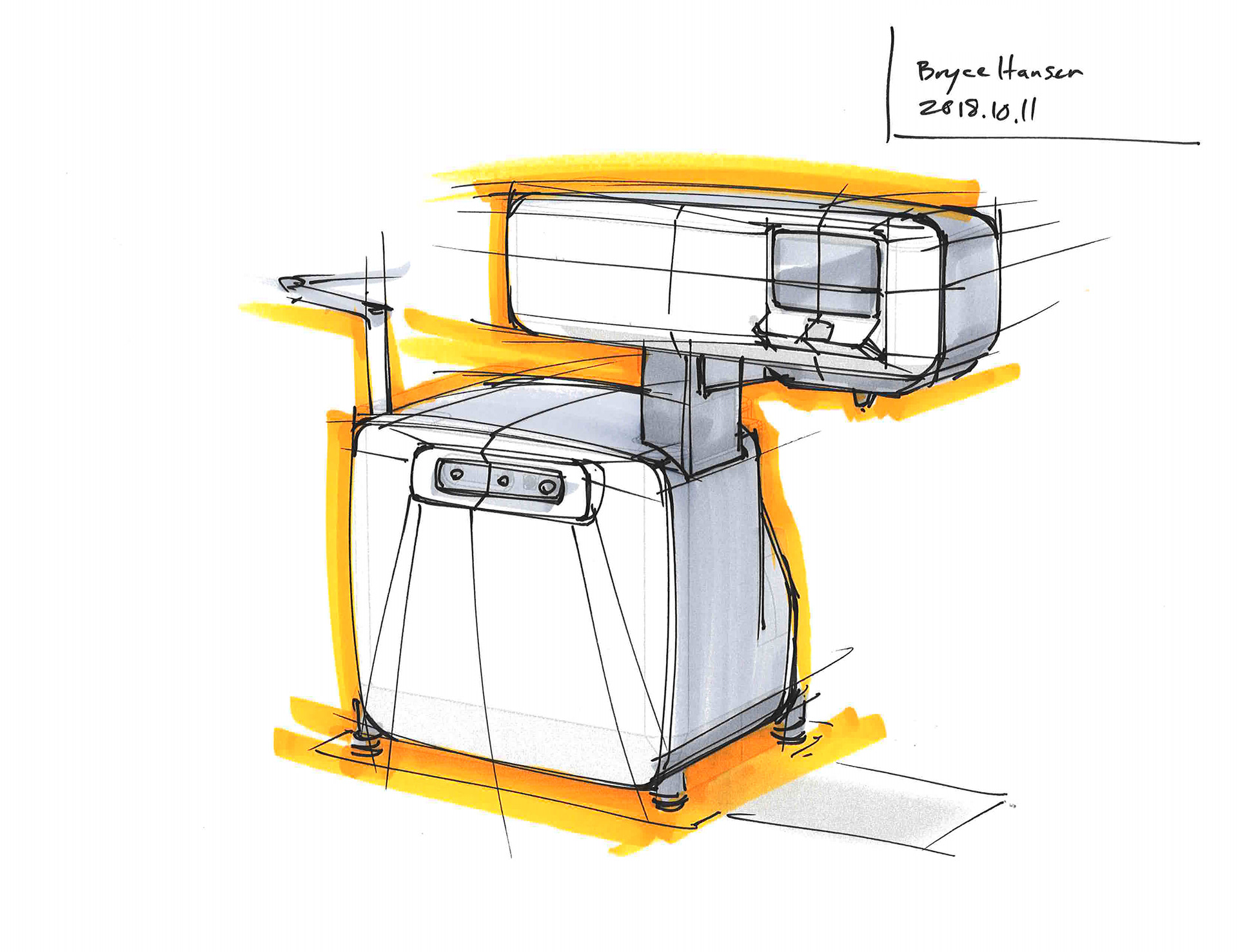

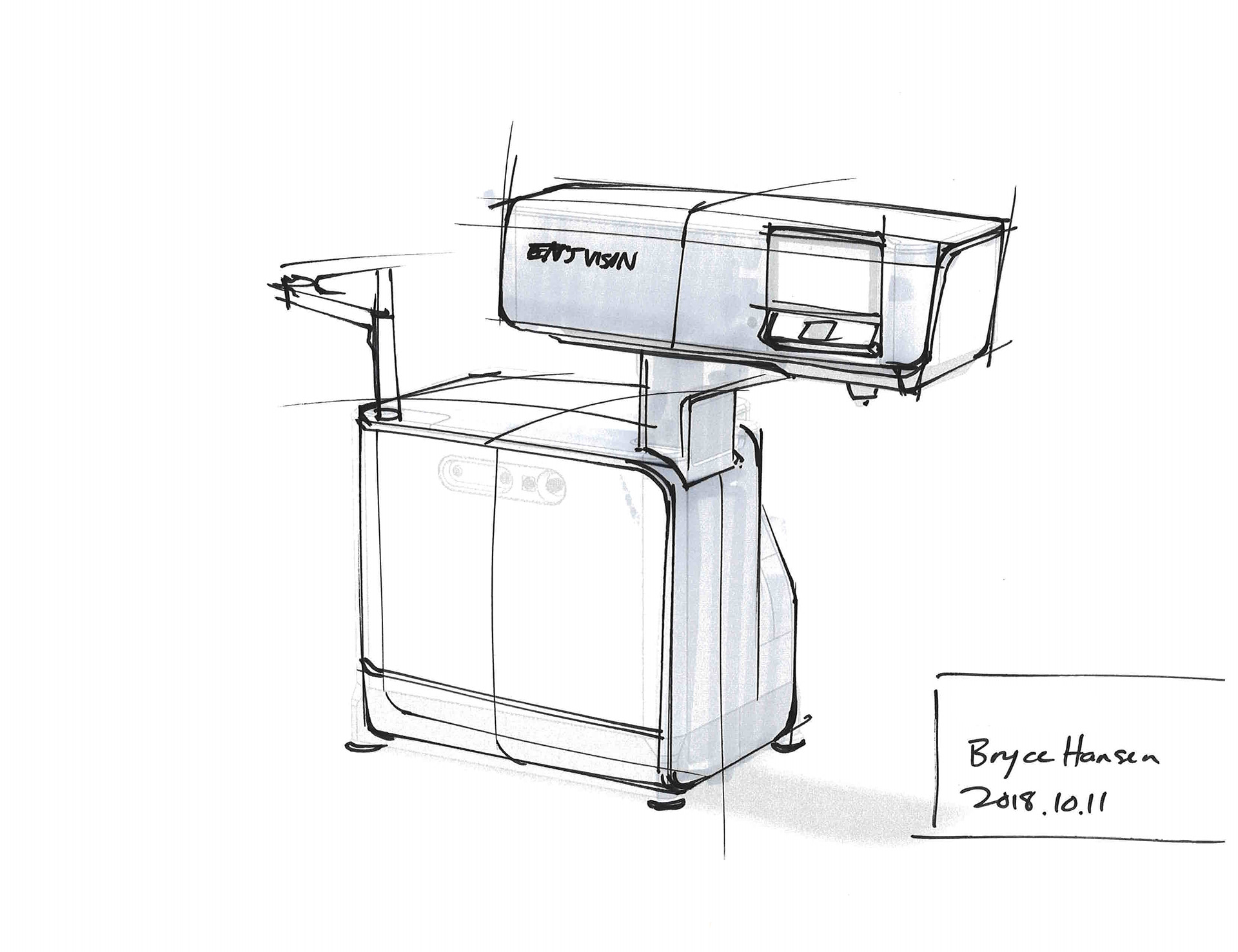

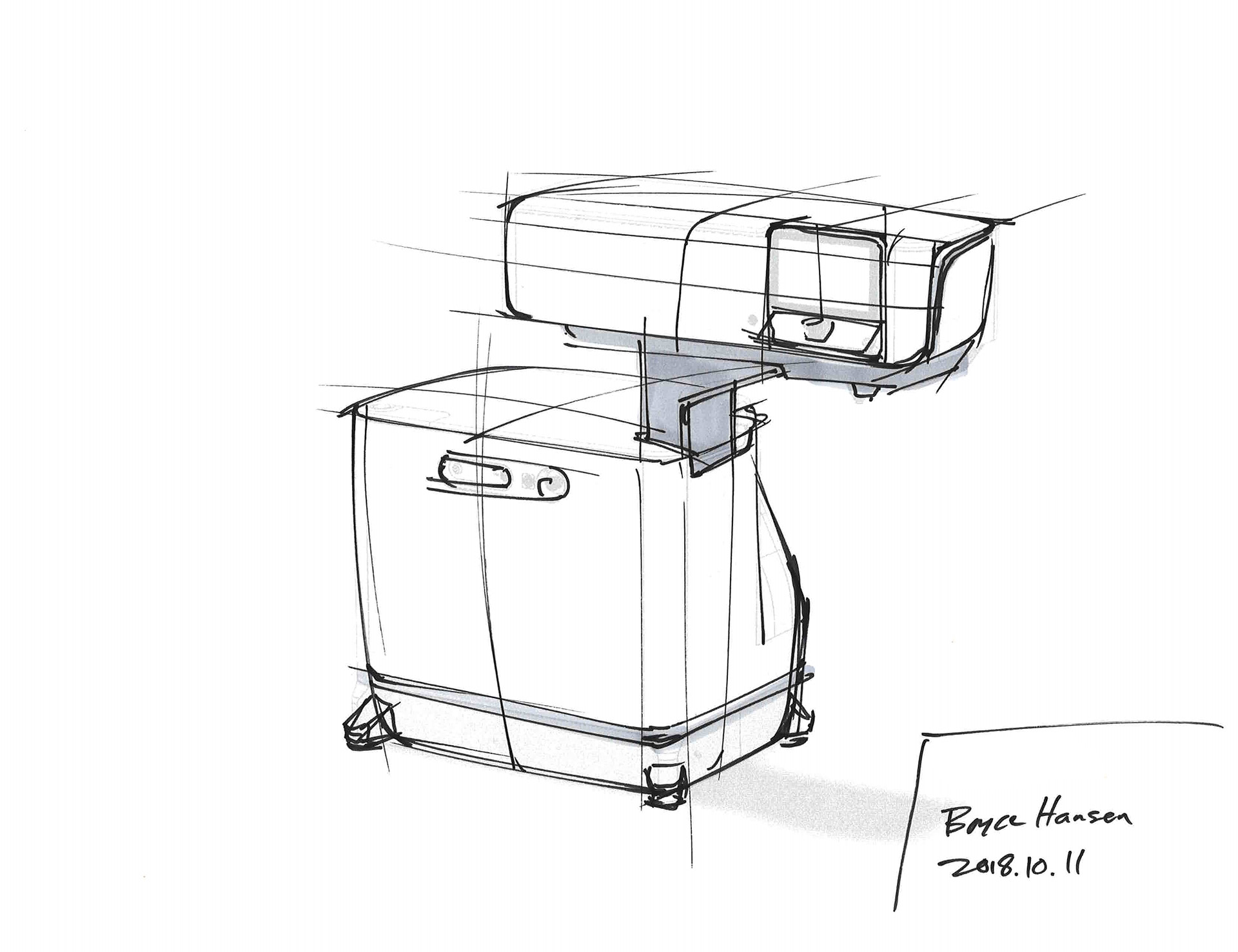

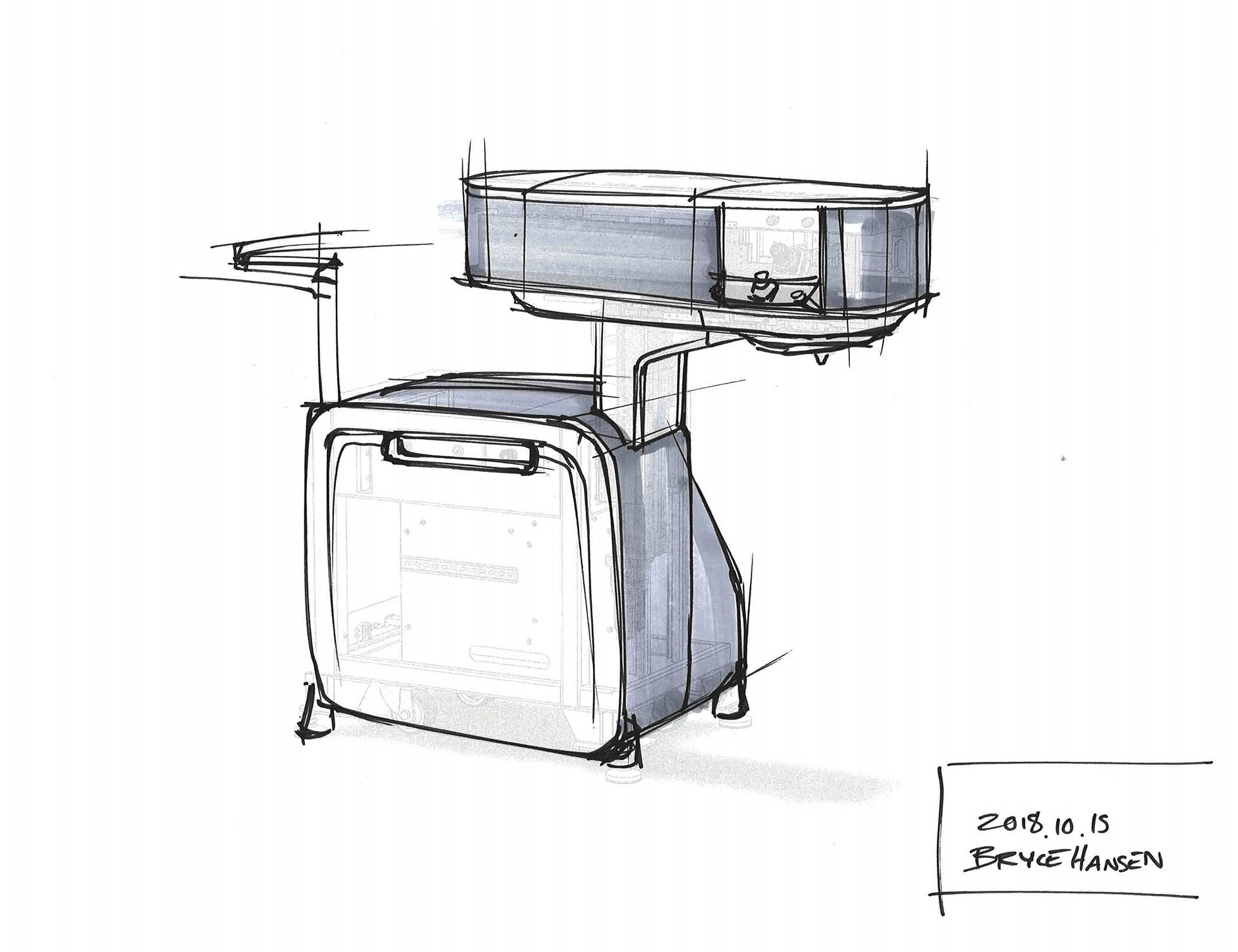

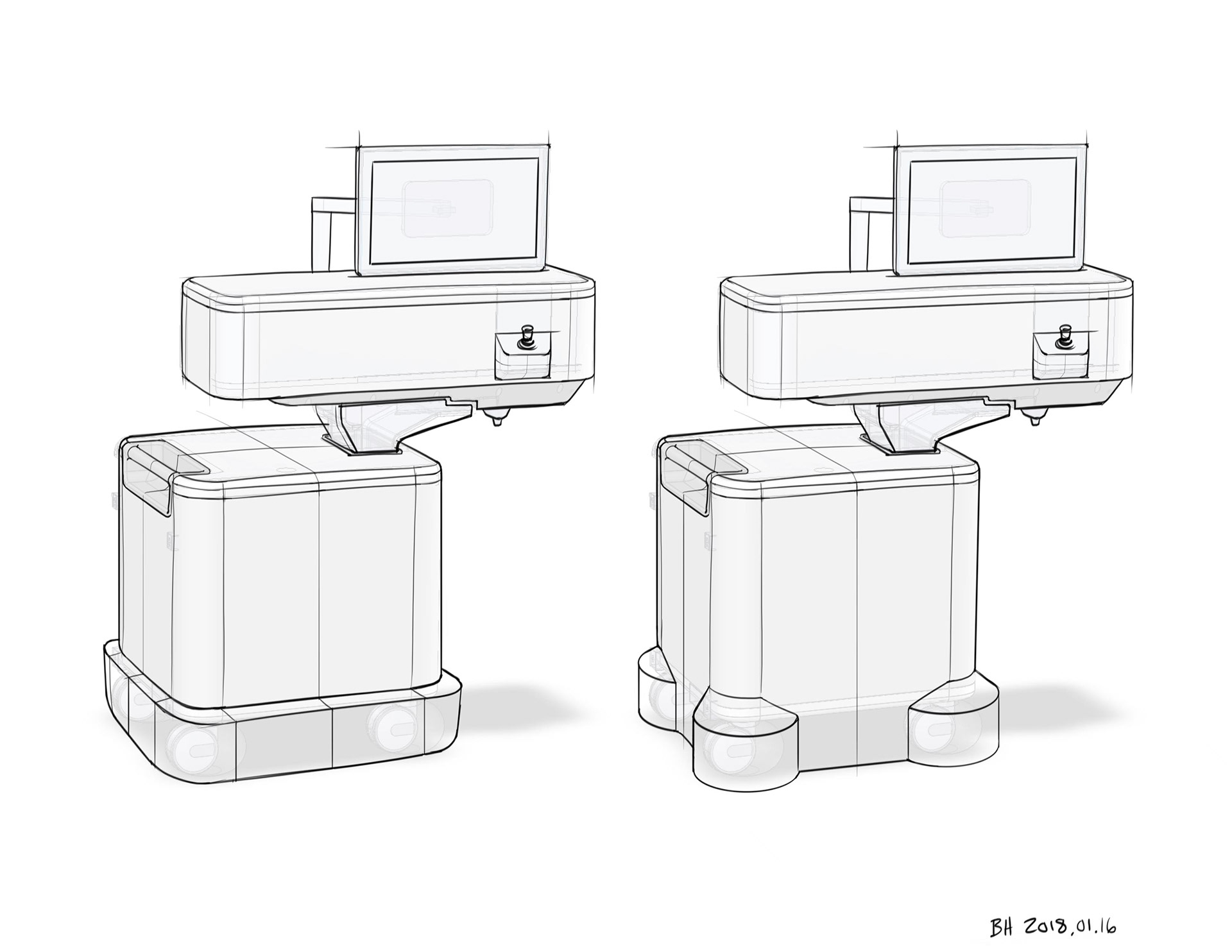

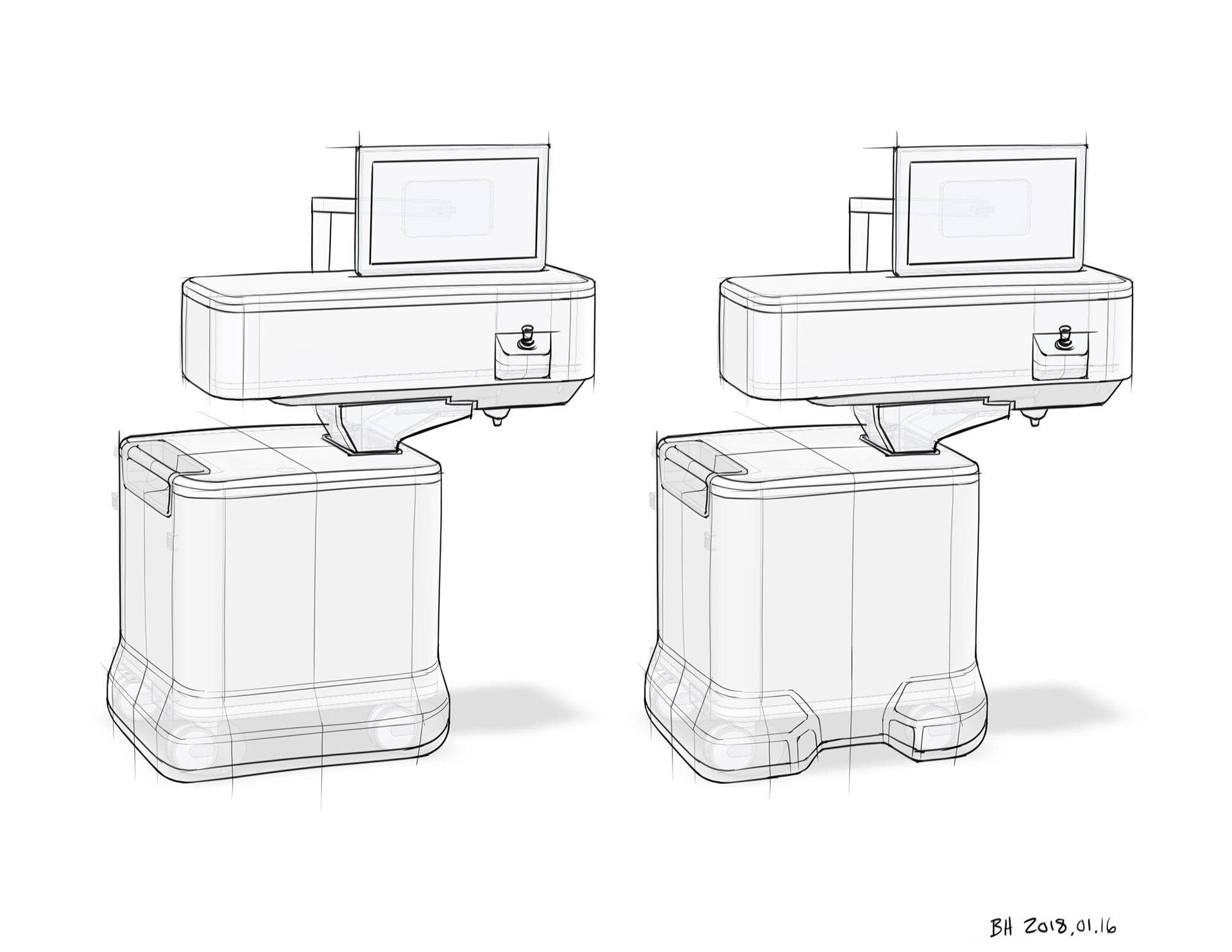

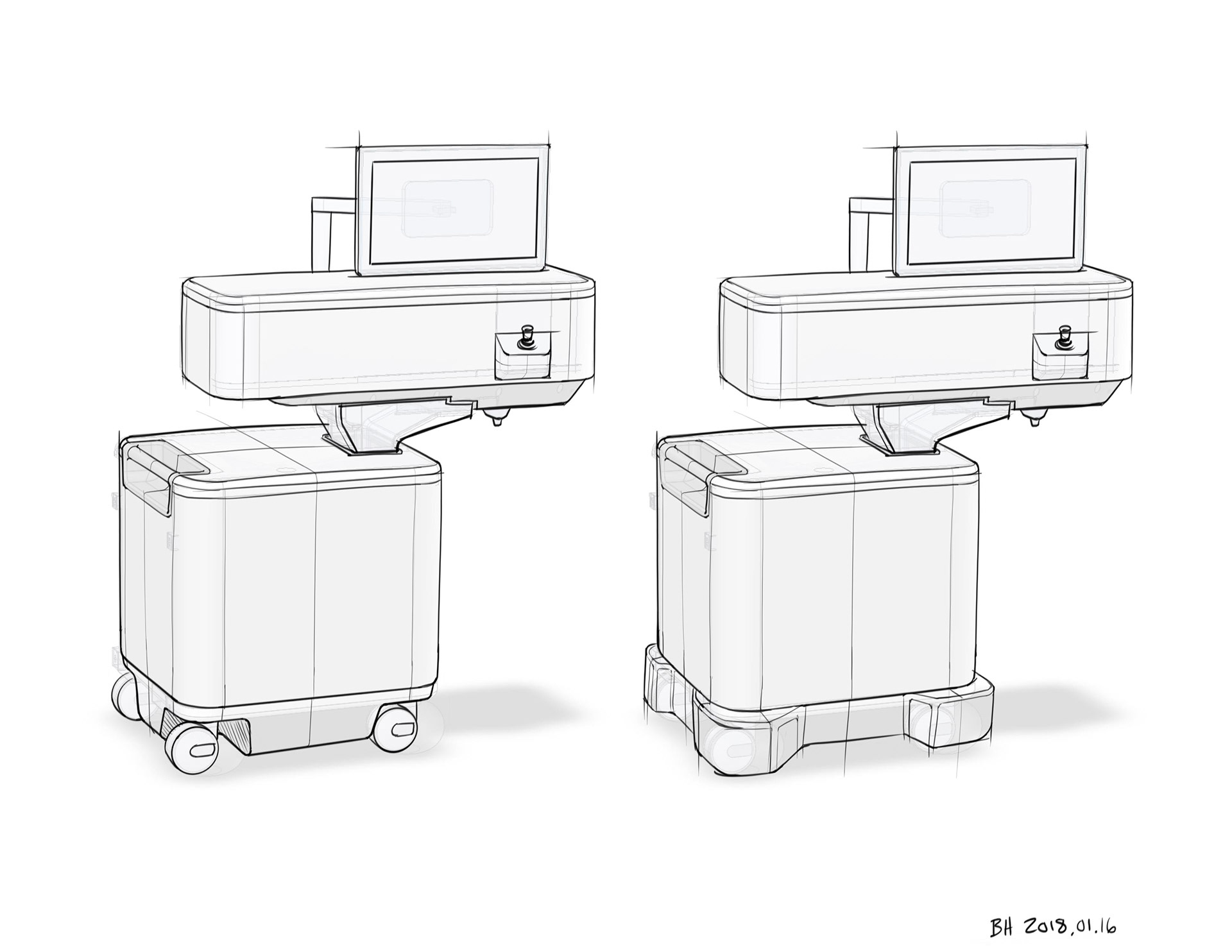

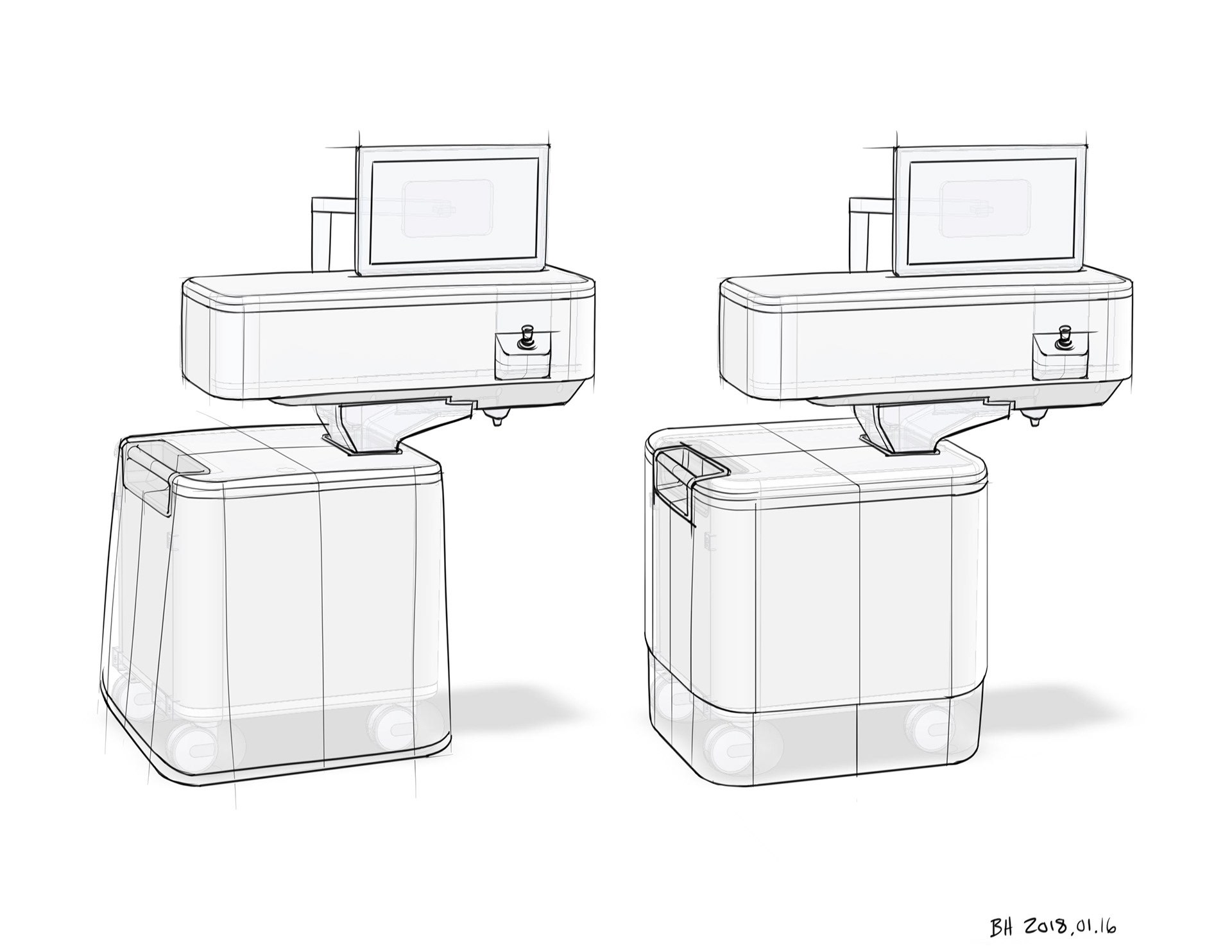

Sketch concepts I drew.

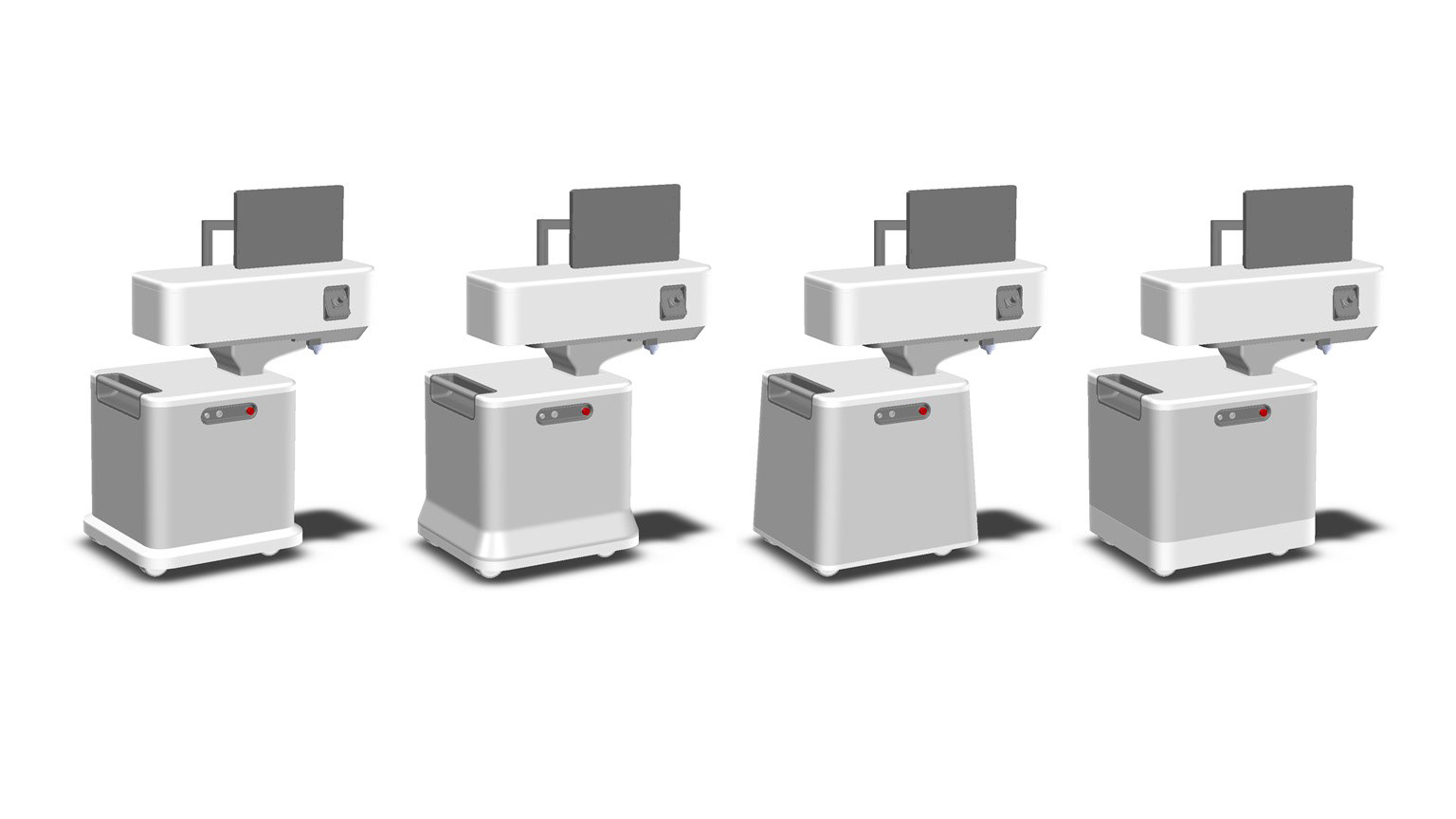

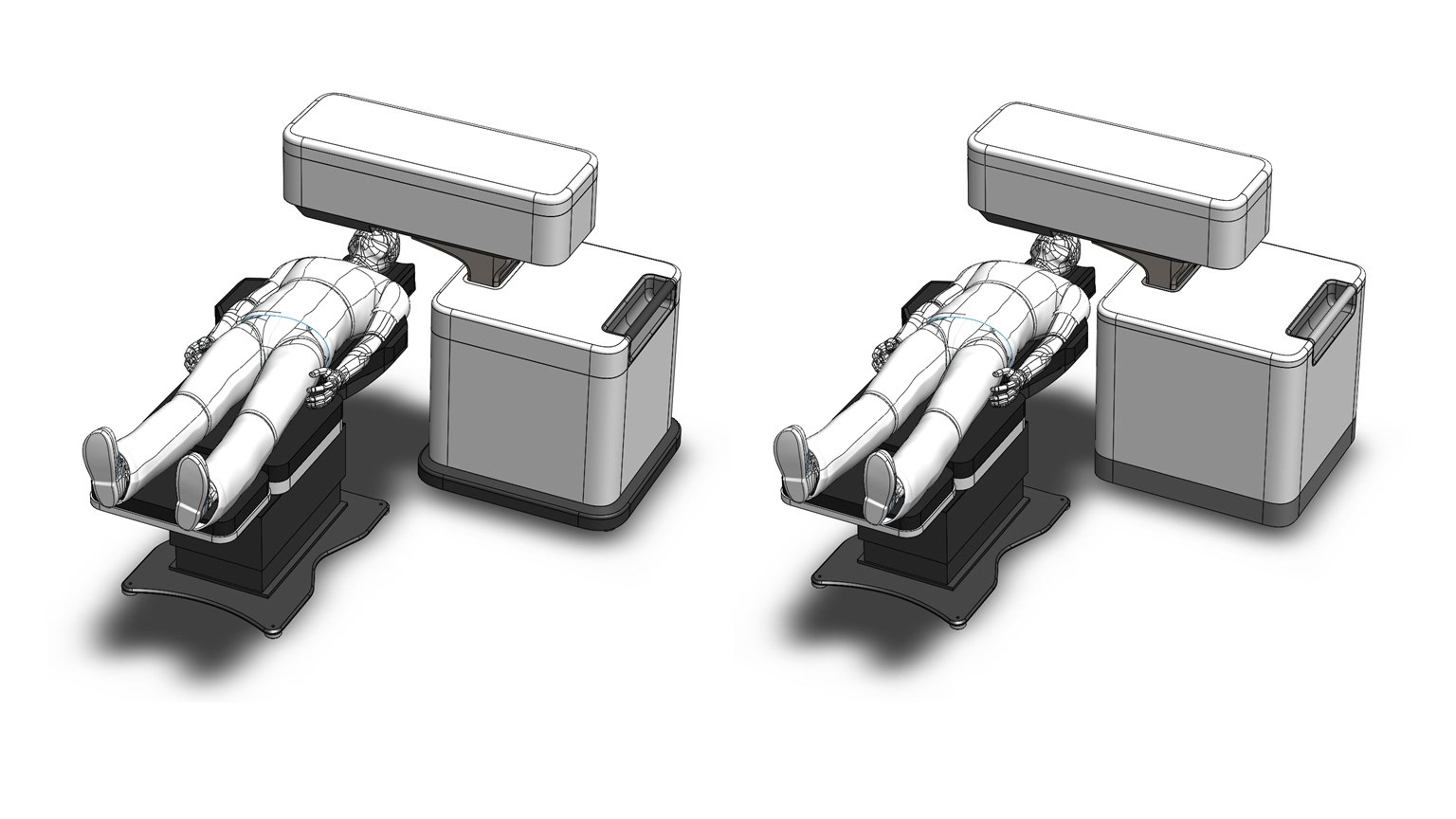

Some concepts I 3D modeled in Solidworks.

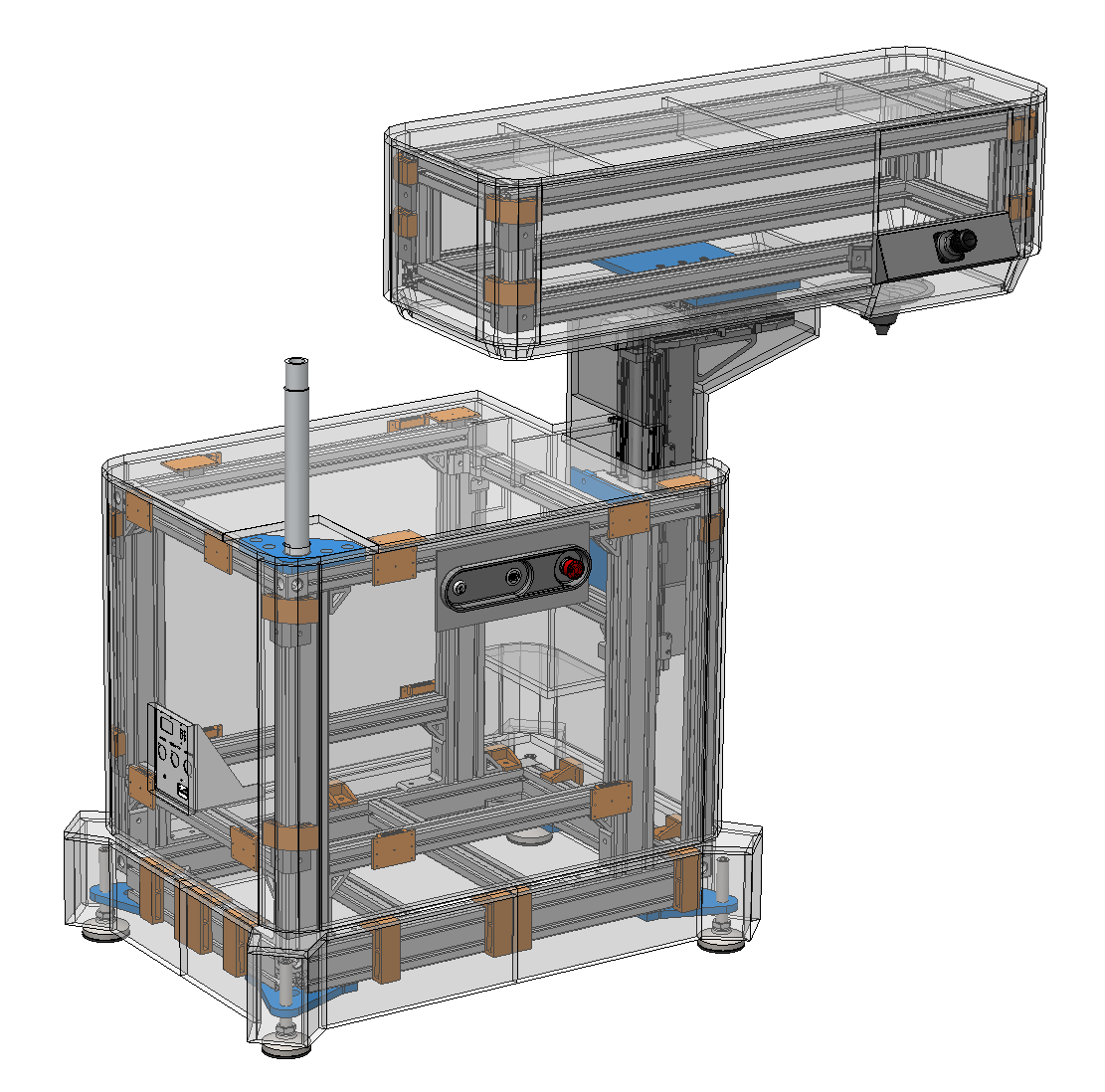

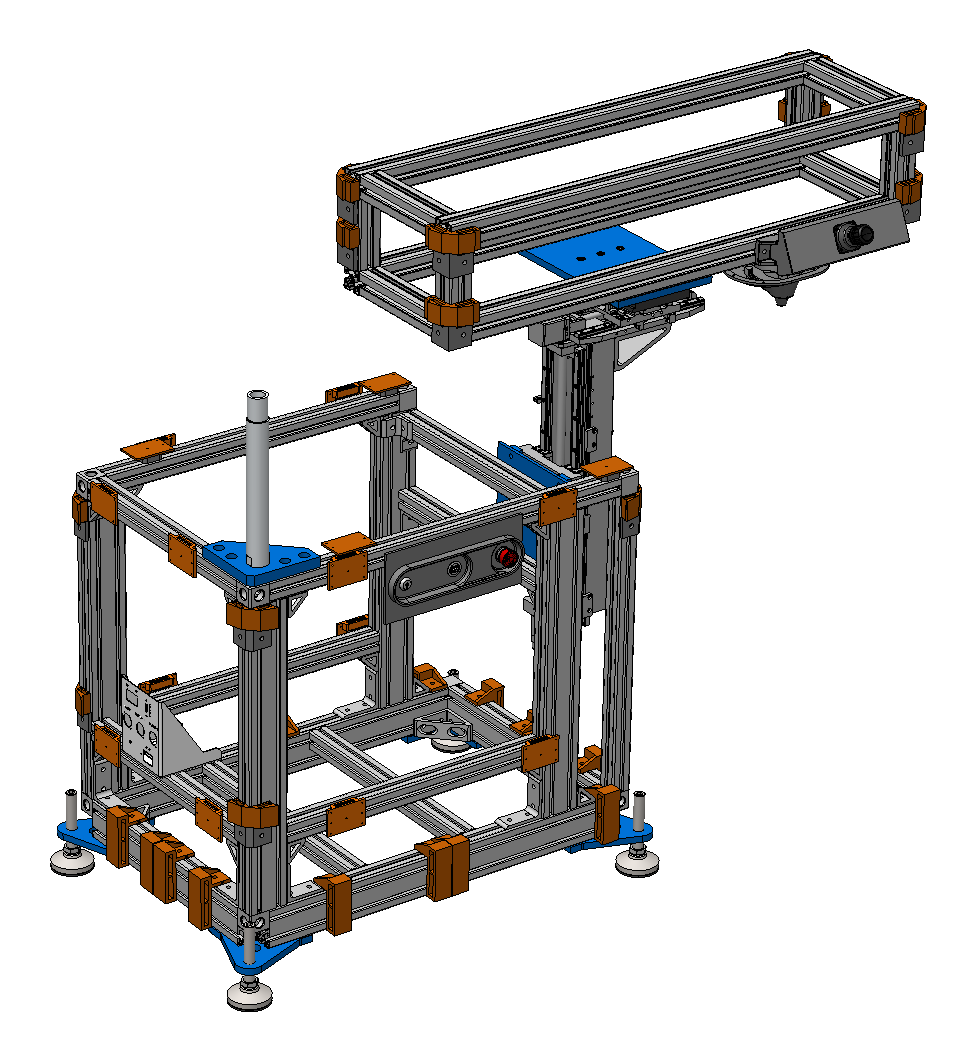

For the full scale appearance model, I designed the 80/20 aluminum extrusion assembly, 3D prints, foam core sizes, how it would all fit together, and designed parts to be machined. There were also some parts from engineering that they had me incorporate.

In the screenshots below, gray is 80/20, blue are machined parts, and the orange are 3D printed parts.

This is an image of the in-process assembly of the 80/20 aluminum frame, some machined parts, and 3D printed brackets for hanging the foam core on so that it could easily be removed.

I was able to travel to California multiple times to create/assemble the model/s onsite at JNJ Vision.

I mounted the components from the engineers to the 80/20, and they got that working so that the gantry moved on the appearance model/s.

This was the first round of the appearance model finished with the foam core hung on the 3D prints. Later the foam core was replaced with a higher fidelity updated panel design.

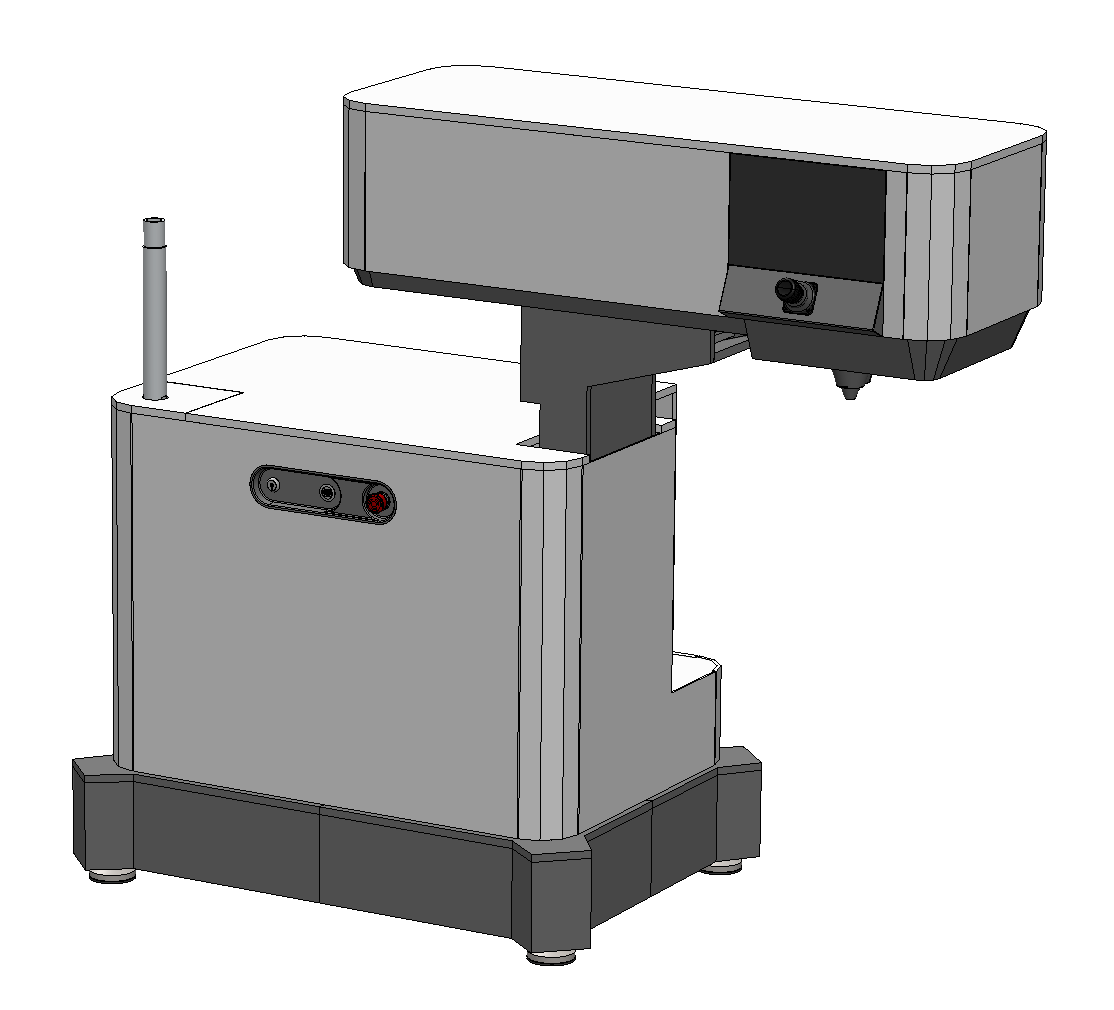

Later we updated the full-scale appearance model, and here is a screenshot of panel breakup I modeled in SolidWorks for that model update. These panels were 3D printed and painted by an outside company, and then assembled to the 80/20 frame.

Screenshot of updates to the frame for the new panel design.

Frame update for the round 2 panels.

Here is the finished product design on the companies website. I was gone before the below final design was created.